CO2 Renu® Technology

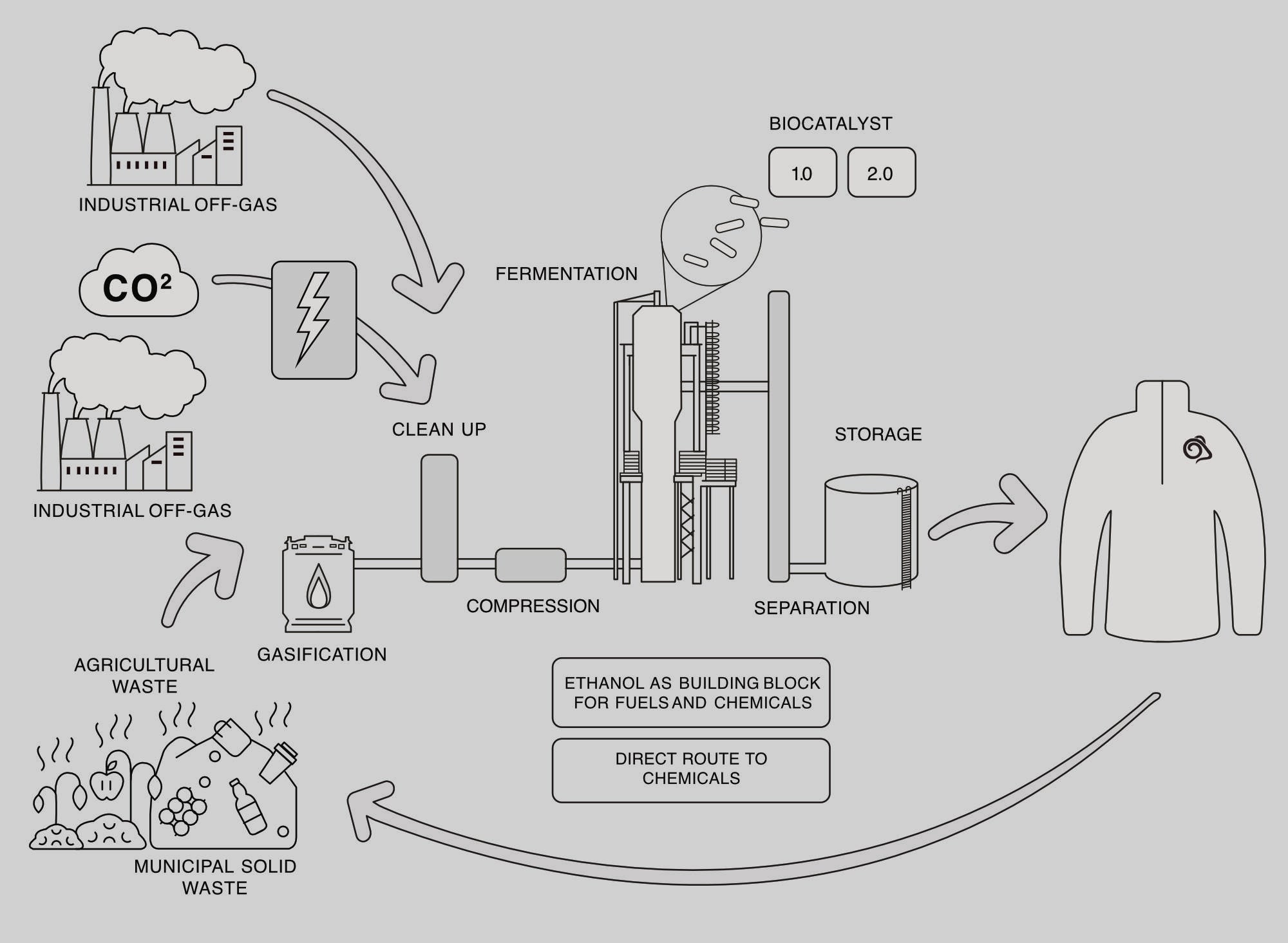

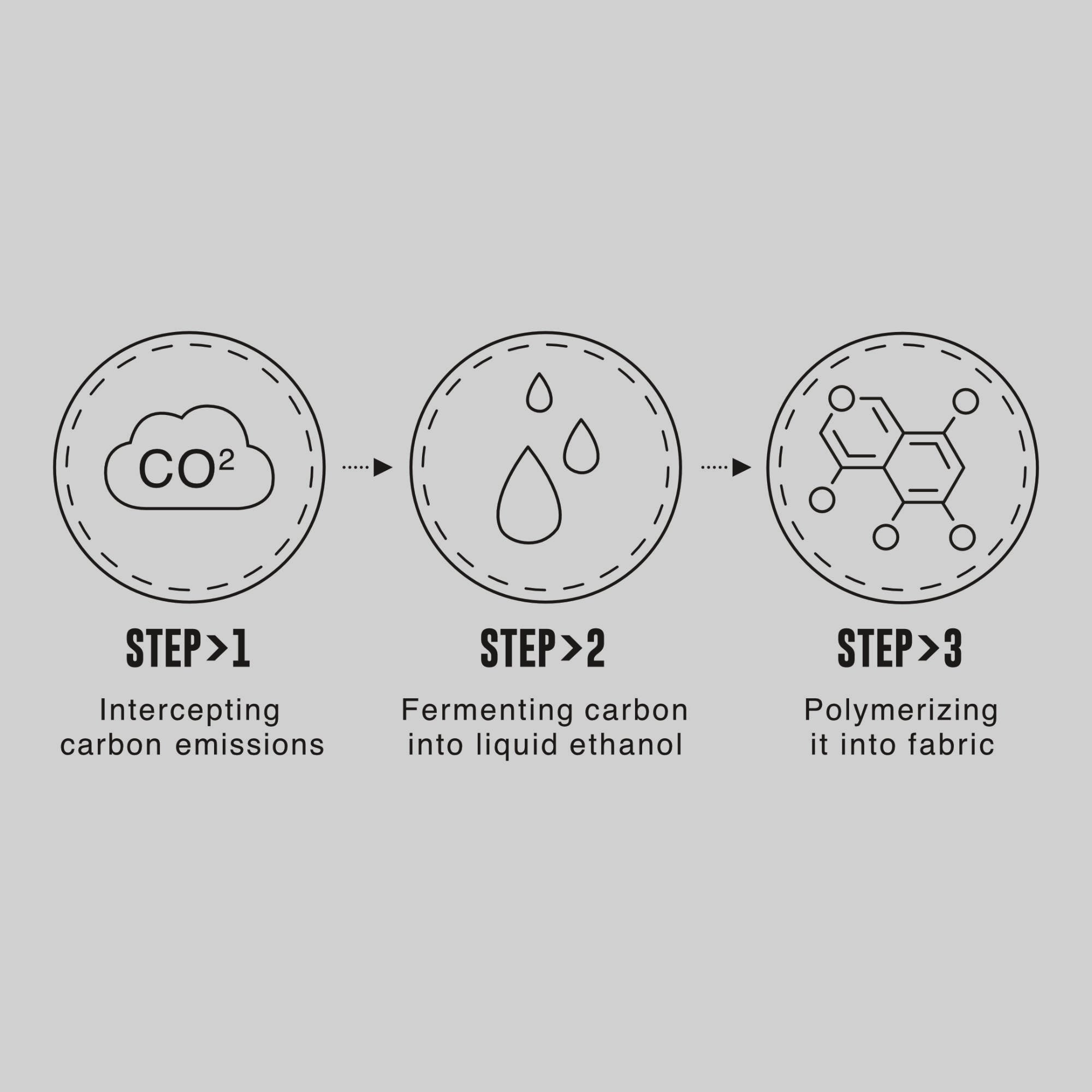

Craghoppers’ CO2 Renu® fabric uses 100% recycled materials, including up to 30% of fibres made from captured CO₂ emissions. The process works with industry-partner LanzaTech to intercept CO₂ waste, convert it via fermentation into building-block chemicals, and then produce polyester yarns—giving “pollution” new purpose in performance apparel. This technology helps reduce the carbon footprint of the fabric while creating high-quality recycled fleece and outerwear.

Filters

Men's • Black Pepper

Men's • Black Pepper

Men's • Blue Navy

Women's • Blue Navy

Women's • Blue Navy

Women's • Ecru

Women's • Light Grey Marl

Men's • Macaw Red

Women's • Sedona

Made with Pollution

What is CO2RENU?

The Science

Carbon is a chemical element that occurs in nature both in pure form (e.g. graphite or diamonds) or as a part of chemical compounds - such as CO and CO₂.

What is special about this element is that carbon has the ability to form complex molecules, and therefore shows the greatest variety of chemical compounds of all elements - that is, carbon can take on a variety of forms in combination with other elements.

Industrial activity generates waste gases that usually end up as CO₂ emissions; for instance, CO and CO₂ waste gases are produced during steel manufacturing.

We worked with climate tech company, LanzaTech who has a platform to capture and convert these waste emissions into the building blocks for textiles manufacturing via the process of fermentation. Much like traditional fermentation that uses sugars and yeast to make alcohol, this process uses waste carbon emissions and a special microbe to make ethanol. This ethanol can be converted into mono ethylene glycol (MEG), a key ingredient in the manufacture of polyester.

In this way ethanol from pollution can be converted into the material needed to make the fleece. We refer to these yarns as Bio3 Carbon Smart Polyester. When blended with recycled polyester in the next step, then named CO2Renu.